Gearboxes

For Seeders And Fertilizers Machines

Buying is easy: Contact us and we'll send it!

Key Sliding

The gearboxes for speed selection are applicable to systems of dosage of seeds and fertilizers in seeders to replace the old;train of chains and gears.

The system of key sliding has a specific number of speeds.

These kinds of system are managed by a different number of handles according to the model. It’s consisting of a couple of gears set for each handle.

The driven gear set is fixed to the shaft by a fixed key and the driver gear set has a sliding key that only gives transmission to one of the gears of the set.

In this way, according to the combination of the gear in the different shafts is the ratio of the gearbox. The position of the sliding key is managed by the handles.

Characteristics | SW2006 | SW2010 | SW2011 | SW2015 | |

|---|---|---|---|---|---|

| Speed number | 54 | 16 | 27 | 32 (x2) | |

| Speed ratio | Range | 1:0.18 1:3.51 | 1:0.94 / 1:2.14 1:0.47 / 1:1.06 (***) ———– 1:0.44 / 1:2.65 1:0.38 / 1:2.24 (***) | 1:0.54 1:2.86 | 1:0.36 1:3.19 |

| Variation between speed | 3 – 12 % | 6 % ———– 12 % | 6 % | 5 – 12 % | |

| Torque [Kgm] | 18 | 12 | 8 | 12 | |

| Output sense | CW-CW (*) | CW-CW (*) | CW-CW (*) CW-CCW (**) | CW-CW (*) | |

Gear Sliding

The gearboxes for speed selection are applicable to systems of dosage of seeds and fertilizers in seeders replace the old train of chains and gears.The system of gear sliding has a specific number of speeds.

These kinds of system are managed by a different number of handles according to the model.

It’s consisting of a couple of Gears Sub-Assembly welded for each handle. Each Gears Sub-Assembly has 2 or 3 gears.There are the same number of fix and sliding Gears Sub-Assembly.

The position of the sliding Gears Sub-Assembly is managed by the handles. The handles move for both sides, movin;the Gears Sub-Assembly in order to make agree only one gear of each Gears Sub-Assembly. In this way, according to the combination of the gear in the different Gears Sub-Assembly is the ratio of the gearbox.

|

Characteristics |

SW2003 |

SW2003 A |

SW2014 |

|

|---|---|---|---|---|

| Speed number | 27 | 27 | 18 | |

| Speed ratio | Range | 1:0.45 1:1.98 | 1:0.45 1:1.98 | 1:0.45 1:1.19 |

| Variation between speed | 6 % | 6 % | 6 % | |

| Torque [Kgm] | 8 | 18 | 24 | |

| Output sense | CW-CCW (*) | CW-CCW (*) | CW-CCW (*) |

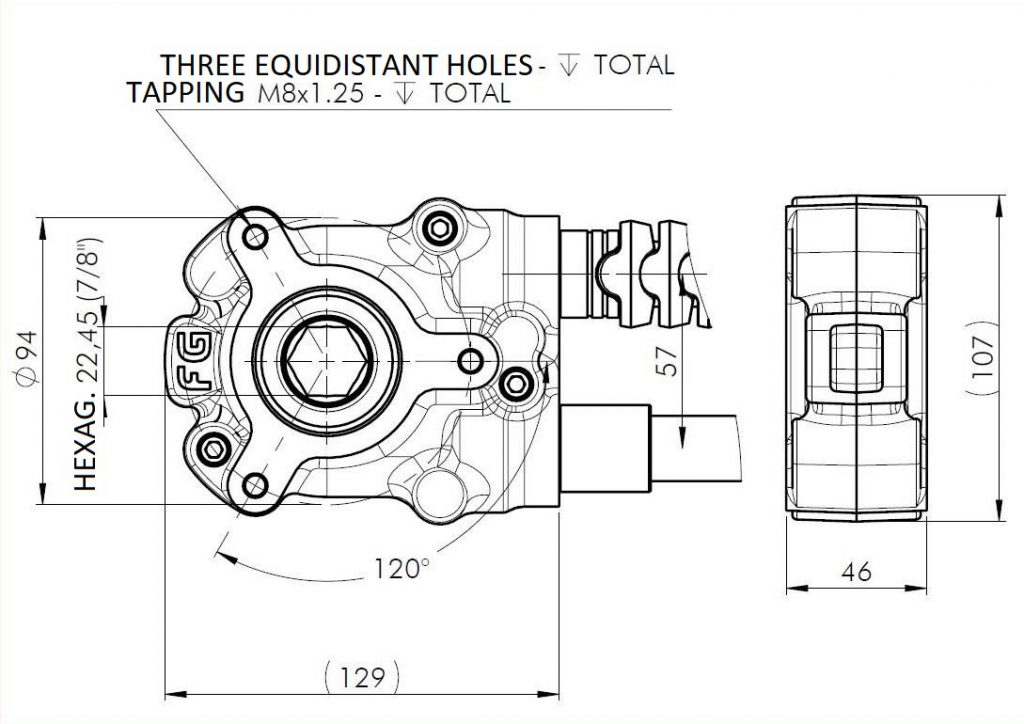

Flexible transmission-Gearbox S. P. 910

In addition, it could be placed the S. P. 911 gearbox (cut per line): it is placed in the flexible transmission, one for each line. Drive 12V 750 mA. (The solenoid is energized only to cut off the drive – (Normal closed NC)

Housing Material: cast aluminum

Shafts/ gears: SAE 8620 steel-hardened

Support shafts: sealed bearings

Lubrication: Multi-Use lithium grease NLGI 2-75 GR.

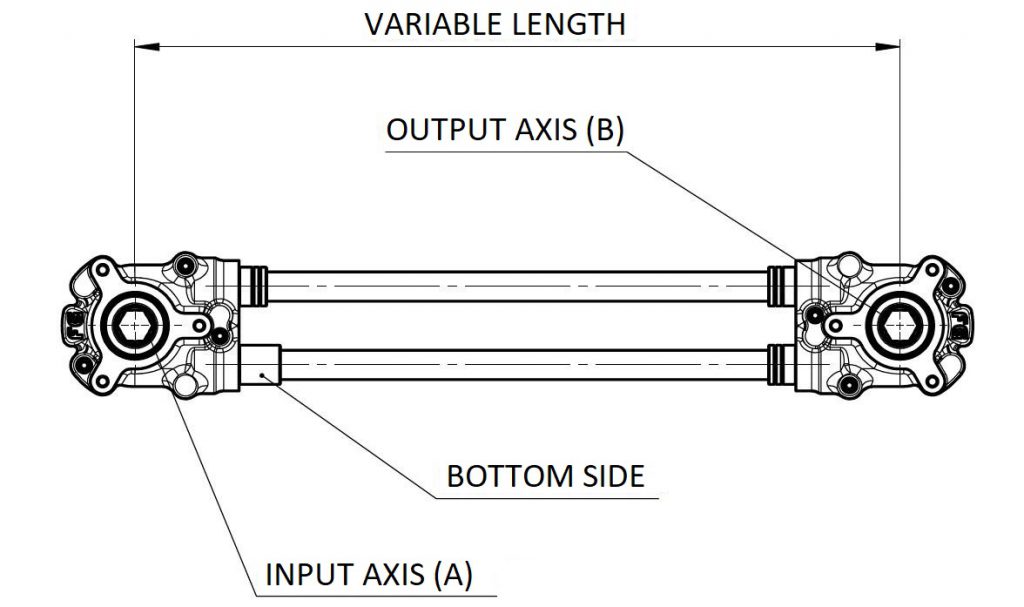

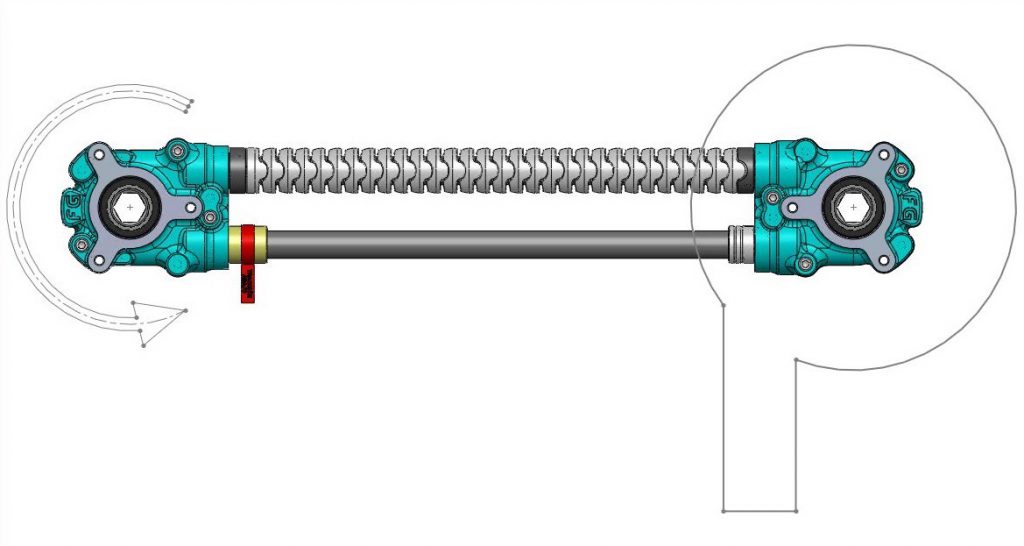

Flexible transmission vs square boxes and cardan bar system

- Accuracy rotation

- Greater flexibility

- Rotations Instantaneity between input and output.

- Absorbs planting row-unit misalignments

- Low rated and constant

- Torque Constant angular velocity is independent of parallelogram movements which enable better planting quality.

- Lower weight. Moisture-proof, dust-proof, etc.

- Easy installation.

- Durability Maintenance-free Line cutting (electric or manual) can be added.

Encoding

Box coding: 001860 – SP910 (786.6-138E)

Factory ID: 001860

Box name: SP910

Center distance: 786.6 mm

Number of links: 138

Distance between centers

Overall Dimensions

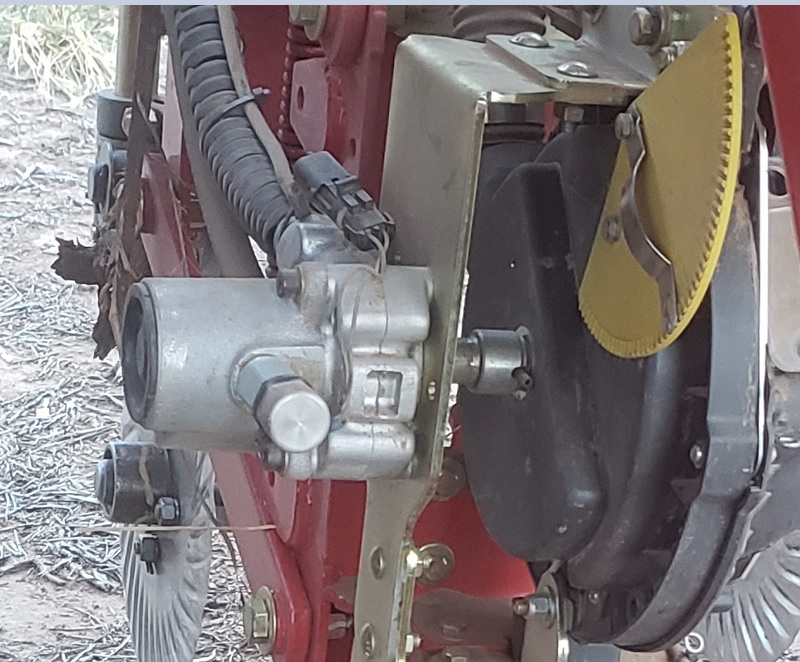

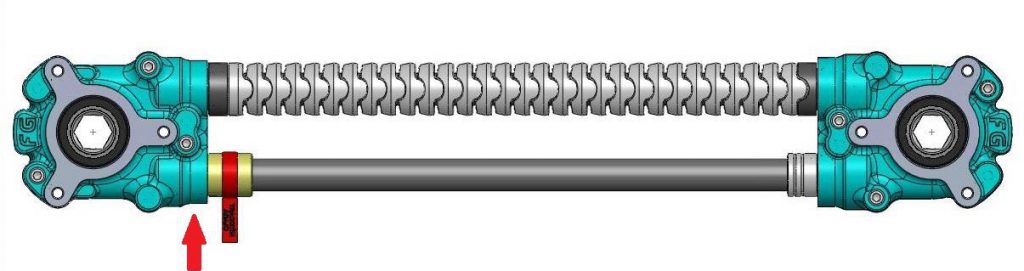

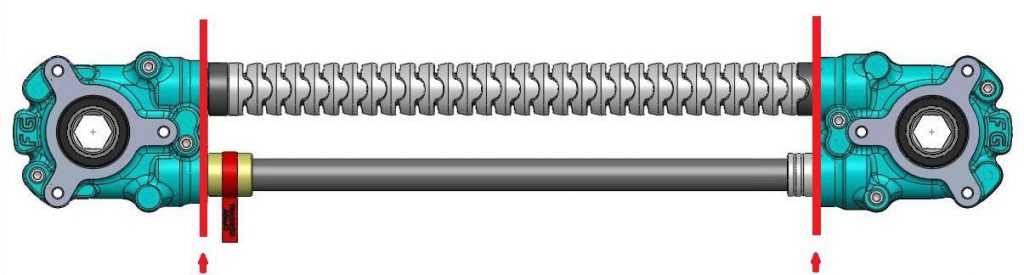

Installation

The golden bushing must be placed on the traction side at the bottom, taking care that the fronts of the two gearboxes are parallel (marked with red lines)

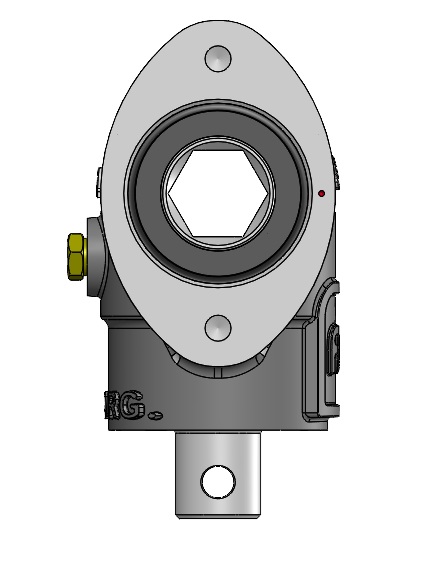

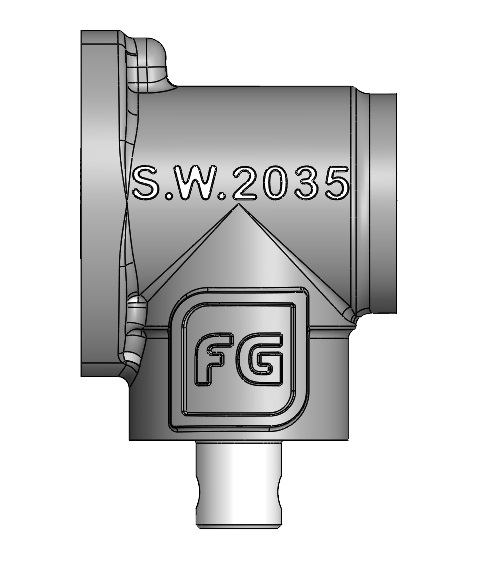

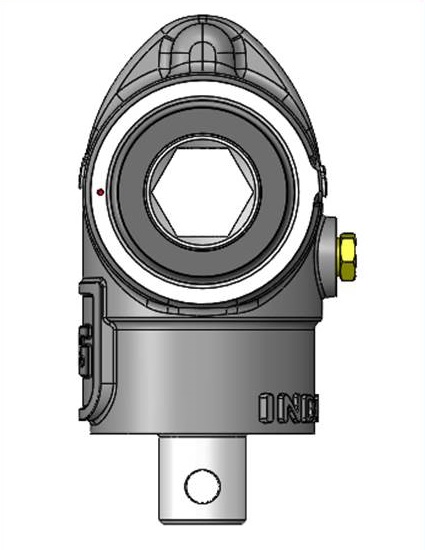

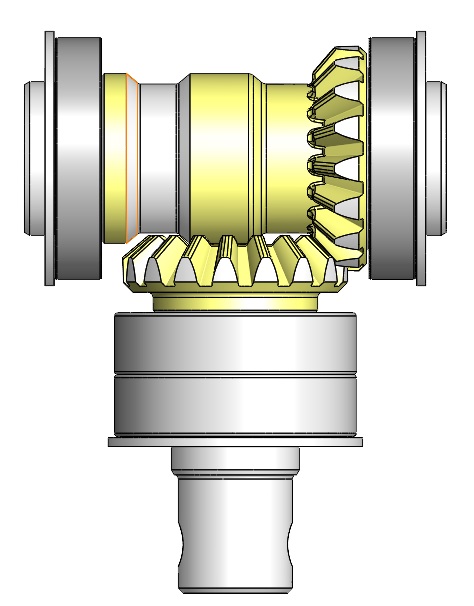

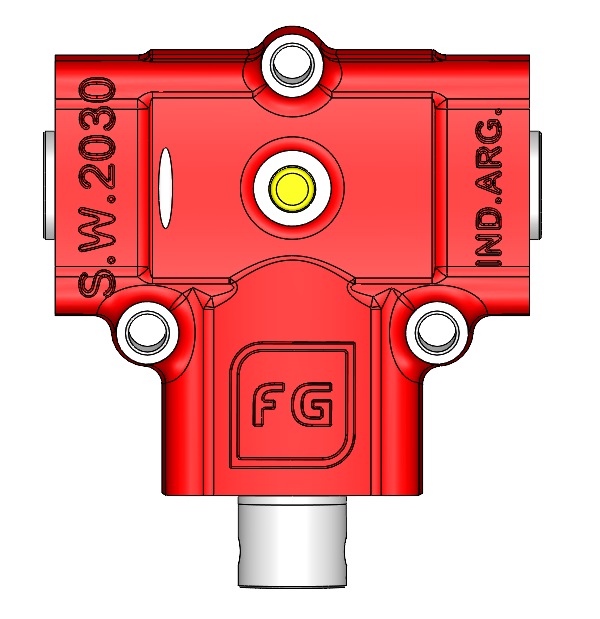

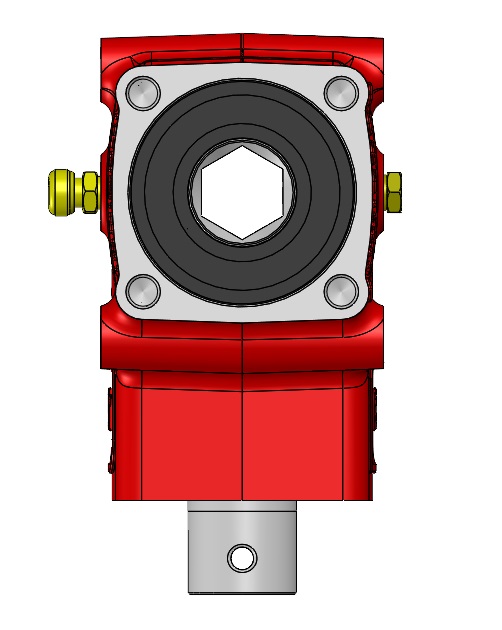

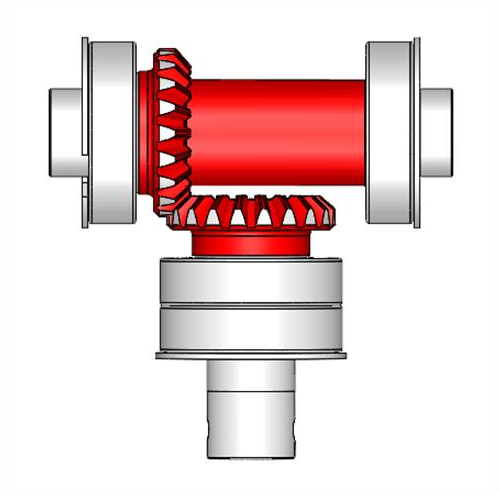

Square gearboxes SW2030 and SW2035 / 90 degrees power transmission.

A square gearbox can be placed at the input (Drive) and another at the output (on the axis of the dispenser), and connecting them with a cardan and thus avoid the use of chains. All parts are machined on CNC machines under strict quality control.

Gearbox S.W. 2030: Large square box cod. 001570, used to transmit to all planting lines. Download technical sheet (in Spanish) ![]()

Housing Material: cast aluminum

Shafts/ gears: SAE 8620 steel hardened

Support shafts: sealed bearings

Lubrication: Multi-Use lithium grease NLGI 2-75 GR.

Housing Material: cast aluminum

Shafts/ gears: SAE 8620 steel hardened

Support shafts: sealed bearings

Lubrication: Multi-Use lithium grease NLGI 2-75 GR.