CONSTRUCT A SINGLE-DISK OPENER NO-TILL SEEDER: WITHOUT PROBLEMS

We transfer technology to agricultural machinery manufacturers, helping them to design and produce quality no-till seeders.

CONSTRUCT A SINGLE-DISK OPENER NO-TILL SEEDER: WITHOUT PROBLEMS

We transfer technology to agricultural machinery manufacturers, helping them to design and produce quality no-till seeders.

Benefit from our experience!

Do not go through a hard and expensive learning curve.

The presence of insufficient or, even worse, contradictory information will surely lead you to make wrong decisions, increasing the costs when developing an efficient prototype. Thirty years ago in Argentina, we started transitioning to direct sowing, learning from our successes and failures. We have a set of factories specialized in agricultural equipment specifically designed for no-till seed drills. Only use local suppliers with proper experience.

Projects and clients

ARGSELMASH has successfully transferred Argentine knowledge and experience to produce a quality no-till seed drill. Today, we assist companies in Latvia, Russia, Ukraine, Australia, and Spain in projects to adapt seeders and fertilizers to very different climates and soils.

Some of our projects

Seeder Beriguinia - Russia

Seeder: “Beriguinia AP-421”.

Manufactured by: “Podshipnik”

Location: Ust-Labinsk, Krasnodar.

Country: Russia.

Components sold: Single disc openes, variable speed drives and seed, fertilizer and pasture dispensers.

Watch the full video On Youtube. (With English subtitles)

Seeder Turbosem - Ukraine

Seeder: “Turbosem II”.

Manufactured by: “Agro-Soyuz”

Location: Dnipropetrovsk.

Country: Ucrania.

Components sold: Single disc openes with parallelograms.

Watch the full video On Youtube. (With English subtitles)

Seeder Abelites - Latvia

Seeder: “Abelites”.

Manufactured by: “Abelites”

Location: Riga

Country: Latvia

Components sold: Single disc openers with parallelograms.

Watch the full video On Youtube.

Seeder "Томь" - Russia

Seeder: “Томь”.

Manufactured by: “OOO Agro”

Location: Kemerovo

Country: Russia

Components sold: Single disc openers with parallelograms.

Watch the full video On Youtube.

Some of our clients

Agro Soyuz (Ukraine) – Openers with parallelograms

BDM-Agro (Russia) – Seeders G210 – G600

Podshipnik (Ruыsia) – Seeder Bereginia 421- John Deere type opener.

NAIR (Russia) – Components and spare parts.

NewTone (Russia) – Openers with parallelograms and spare parts.

OOO Agro (Russia) – Openers with parallelograms

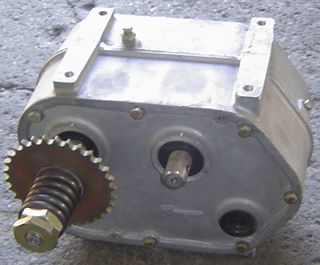

KITE (Hungría) – Gearboxes.

Abelites (Latvia) – Openers with parallelograms

Reino de los Mallos (Spain) – Openers with parallelograms

Toowoomba Engineering – (Australia) – Openers with parallelograms

What do our customers think?

What are we gonna do?

We will prevent you from wasting money, efforts and time on the development of a seeder that may, in the long run, end up not adapting correctly to the real needs of your customers.

- Tell us about your project and what your design problems are today.

- We will help you define the necessary components.

- Identify the suppliers.

- To develop the prototype and its field test

- To define the production and supply programs.

In each of those steps we will help you make the right decisions.

We propose you, to build your own seeder.

This new machine will have

Build most of the parts locally

We are your team

Steps for a direct seeding design

The opener seletion

John Deere opener type:

The selection of this opener variant determines that the tool holder bar is activated by the hydraulic system of the chassis, rotating it by 45º to change from the transport position to the working one.

Monodisc with parallelogram:

For this design, the hydraulic system acts on the complete chassis of the seeder to change the position of the sowing trains from transport to working position.

In addition of the selected sowing train must be chosen:

Seed compaction mechanism: There are two main options: the firming wheel and the firming plastic tongue.

Closing the groove: There are two main wheels to close the groove: smooth (for soils with little coverage) and serrated (for soils with a lot of coverage). The choice also depends on the type of soil and the moisture present.

Mechanical seed, fertilizer and pasture dispensers:

The high-quality mechanical seed, fertilizer and pasture dispensers are suitable for the sowing of fine grains, guaranteeing the exact dosage of up to 500 kg/ha.

Gearboxes:

It is crucial to have a reliable and agile system to change the dosage of both seeds and fertilizers. Gearboxes are the most commonly used method.

Speed variator drives- CVT:

The variable speed drives or CVT allow the dosage to be adjusted from 0 to 100% with a single control, which can be manual or electric from the cabin. In addition, some systems offer variable dosing.