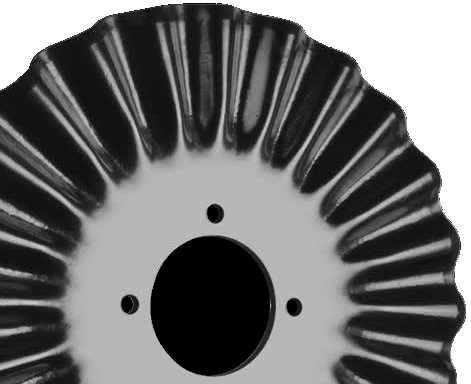

Cutting Blade for Stubble

They are used to facilitate the movement of the seeder and improve the quality of planting when there is a large amount of stubble in the field. The cutting disc is installed in front of the seeding disc.

A cutting disc is placed in front of each planting unit (for cutting stubble), usually located on the toolbar, and facilitates the placement of mineral fertilizers in the planting line.

The depth adjustment of the seeding and cutting disc is carried out by independent mechanisms. Therefore, changing the tension of the planting unit’s spring does not affect the working depth of the cutting disc.

Cutting Blade Depth Adjustment

Summary:

- In low moisture soils: It is crucial to plant seeds as deep as possible to ensure contact with soil moisture, but without compromising their emergence. The blade should remove the soil without affecting the seed depth. In dry soils, breaking the water capillarity can be counterproductive.

- Blade Depth: It is not recommended to bury the blade too deep, as it can hinder seed germination. A shallower depth helps maintain adequate moisture.

- Blade Selection: In firmer soils, larger diameter blades with fewer waves are preferred for better soil removal and less resistance.

- Working Speed: It should be controlled, especially with blades that have fewer waves, to avoid the “spoon effect” and ensure proper seed-to-soil contact.

Variants

| Blade | Working Width | Number of Waves |

| Turbo >> | 14 mm to 16 mm [0.55 inches to 0.63 inches] | 20 |

| Dura Fluted >> | 8 mm to 10 mm [0.31 inches to 0.39 inches] | 38, 50, 60 |

| 38 mm to 40mm [1.50 inches to 1.57 inches] 18 mm to 20 mm [0.71 inches to 0.79 inches] 14 mm to 16 mm [0.55 inches to 0.63 inches] | 8 12 24 |

| Rippled >> | 14 mm to 16 mm [0.55 inches to 0.63 inches] | 18 |

| Radial >> | 7 mm to 9 mm [0.28 inches to 0.35 inches] | 20 |

| Direct >> | 9 mm to 11 mm [0.35 inches to 0.43 inches] 7 mm to 9 mm [0.28 inches to 0.35 inches] | 20 30 |

Cutting Blade Auxiliaries

Skids for the Turbo Blade

- Protection Against Obstructions: By being placed on the sides of the blade, the skids protect against the accumulation of crop residues or soil that could obstruct the blade. This is especially important in fields with a high amount of residues or in soils prone to compacting or forming clods.

- Stability: The skids provide lateral stability to the blade, helping to maintain a straight and precise seeding line. This is particularly beneficial in uneven terrains or challenging seeding conditions.

Residue Sweeper for Seeders

The residue sweeper for seeders is an essential agricultural implement in direct seeding. Here are some comments on its application:

Crop Residue Management: The residue sweeper effectively moves previous crop residues out of the seeding line. This is crucial to prevent these residues from interfering with the proper placement and coverage of the seeds.

Improved Seed Emergence: By clearing the seeding line, the residue sweeper facilitates a more uniform and faster seed emergence. Residues can impede the seed’s adequate contact with the soil, negatively affecting germination.

- Soil and Moisture Conservation: Although the residue sweeper removes residues from the seeding line, it does not completely eliminate soil cover. This helps maintain the benefits of cover, such as moisture conservation and erosion prevention.

- Improved Seeding Efficiency: In fields with a high amount of residues, the residue sweeper is essential for efficient seeding. It allows the seeders to operate without obstructions, reducing operational time and costs.

- Adaptation to Different Conditions: For different types of residues and soil conditions, the residue sweepers can be adjusted in terms of height and angle, allowing optimal adaptation to various situations.

- Environmental Considerations: Proper management of residues using residue sweepers contributes to more sustainable agricultural practices, aligned with the principles of conservation agriculture.