Regular Cleaning After Each Use

Single-disc opener units play a vital role in modern agriculture, ensuring precise and uniform seeding in the soil. To maintain their efficiency and extend their lifespan, it’s crucial to provide proper care and maintenance. In this article, we’ll provide a practical guide on how to maintain and care for your single-disc units, ensuring optimal performance in your farming operations.

One of the best maintenance practices for monodisc seeding units is regular cleaning after each use. After completing the planting session, it’s crucial to thoroughly clean the seeding units, removing any seed residues, soil, or crop remnants. Use pressurized water, typically from a pressure washer, and soft brushes to ensure all parts are clean and free of obstructions.

Inspection and Replacement of Worn-out Parts

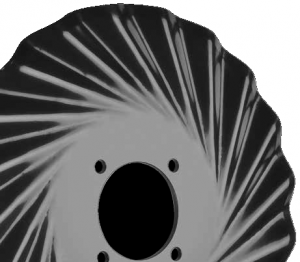

Conduct regular inspections of the seeding units to identify potential wear or damage to parts. Check the discs and blades to ensure they are in good condition and without excessive wear. If you find worn or damaged parts, it’s vital to replace them immediately to prevent irregular or inefficient seeding.

Lubrication and Greasing

Proper maintenance of monodisc seeding units also includes regular lubrication and greasing of moving parts. Use the appropriate lubricant to ensure smooth operation and prevent excessive friction between parts. Pay special attention to pivot points and moving parts to ensure they function correctly.

Proper Storage:

When you’re not using the monodisc seeding units, it’s essential to store them correctly to protect them from the elements and deterioration. Find a dry and clean place to store them and avoid direct exposure to sunlight or moisture. If possible, cover them with tarps or protective covers to keep them dust-free.

Calibration, Adjustments, and Maintenance Records:

Proper calibration of monodisc seeding units is vital for ensuring precise and uniform seeding. Perform periodic calibrations to ensure seeds are optimally distributed. Also, adjust the seeding depth according to the soil type and specific crop conditions to achieve proper establishment.

Maintaining a detailed record of the maintenance performed on monodisc seeding units is advisable. Note down cleaning dates, inspections, parts replacements, and calibrations to have a clear history of the care provided. This will assist you in maintaining scheduled maintenance and identifying wear patterns or recurring issues.

Training and Consultation:

It’s always recommended to receive proper training on the maintenance and care of monodisc seeding units. Consult with the manufacturer or supplier for detailed information on the required maintenance for the specific model you’re using. Moreover, seek advice from agricultural experts or specialized technicians to get additional maintenance tips and tricks.

Conclusion:

Maintaining and caring for your monodisc seeding units is an investment in the efficiency and productivity of your agricultural operations. By following these recommended cleaning, inspection, lubrication, and storage practices, you ensure your seeding units operate optimally and provide precise, uniform seeding every season.

Proper maintenance of the monodisc seeding units will extend their lifespan and contribute to a more efficient, sustainable, and successful agriculture. Remember, taking care of your farming equipment is crucial to achieving the best results and effectively addressing the challenges of the field.