How to Determine the Required Power for Row-Unit?

The technological revolution in the agricultural world has driven the need to maximize efficiencies, especially in the realm of planting. One of the fundamental questions that arise is how many horsepower (HP) is suitable for each row-unit.

Determining Factors

The determination of the required power is not a linear process. It is based on several crucial factors:

- Type of terrain: Not all soils are the same. A clayey terrain may require more power than a sandy one due to its density and resistance. Additionally, the terrain’s incline, whether flat, rolling, or mountainous, also plays a crucial role in this calculation.

- Working speed: The speed at which one wishes to carry out the planting directly affects the necessary power. A higher speed may demand a more powerful tractor to maintain efficient planting.

- Type and design of the seeder: Not all seeders have the same energy demands. Some, due to their features and design, may require more power than others.

- Planting depth: Planting at greater depths generally requires more energy since more force is needed to penetrate the soil deeper.

- Skidding: is a factor that can affect tractor efficiency, indicating issues like a lack of traction or excessive load.

Practical Example:

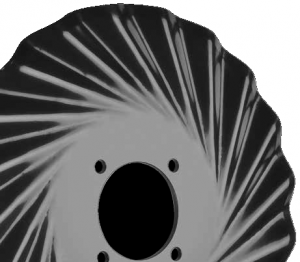

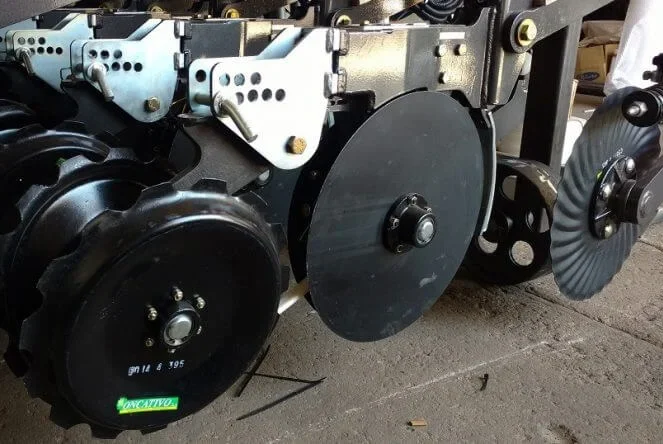

Double-disc:

To calculate the necessary tractor power to work with a 16-row direct seeding machine equipped with a cutting blade or 17″ turbo blade and a double disk seeding train with a double limiting wheel and a double covering wheel:

Considering that the recommended speeds for direct seeding range from 6 to 9 km/h:

– Working speed 8 km/h power per line 7 HP

– Working speed 9 km/h power per line 9 HP

Single Disc:

For calculating the necessary tractor power to work with a 16-row direct seeding single-disc, the first consideration is that it does not need to be equipped with a cutting blade or turbo blade. The seeding train has only one limiting wheel and usually works with a single casting covering wheel.

Under these conditions, the required power consumption is:

– Working speed 8 km/h power per line 5 HP

– Working speed 9 km/h power per line 7 HP

These speeds are a reference as they can vary depending on terrain conditions and deeding depth.

Conclusion

Choosing the right tractor, with the appropriate power, is vital to ensure not only efficiency in the planting process but also the optimization of resources and the extension of the equipment’s lifespan. Currently, each seeder manufacturer advises both the range of planting speeds and the minimum tractor power according to the model in the user manual.

In general terms, for fine grain or soybean sown in rows, the use of the monodisk is recommended for its simplicity of adjustment, low maintenance cost, and lower fuel consumption. We advise visiting: