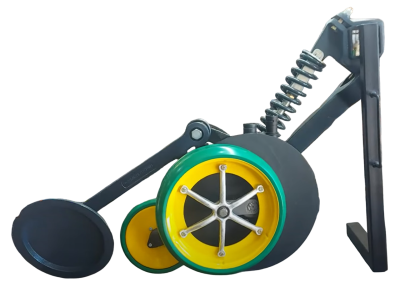

Single-disc opener for no-till farming

ACCURATE - DURABLE - SIMPLE

Buying is easy:

Contact us and we'll send it!

Single-disc opener for no-till farming

PRECISE - DURABLE - SIMPLE

Buying is easy:

Contact us and we'll send it!

Single-disc opener for no-till farming and fertilization: advantages

Single-disc opener for no-till farming: Offers significant advantages compared to other units.

They are more precise and uniform in sowing, more versatile in different soil types, require less maintenance and are more efficient in using seed.

The reduction of variability in depth and distance between grooves translates into greater efficiency and productivity.

In addition, single-disc row units are an excellent option for those who are looking for efficient and high-quality agricultural production.

Preguntas frecuentes

You will sow, practically in any type of soil

Single-disc opener

- It ensures an adequate and consistent seeds positioning.

- Consumes less power.

- Less soil removal

- It helps to retain moisture.

The single-disc opener is the efficient and cost-effective solution you are looking for for your sowing and fertilizing jobs.

Its independent descents for seeds, fertilizers and pastures, and its 18″ diameter flat disc with a 7º inclination and 4 ½” x 15″ levelling wheel make planting precise and uniform, reducing costs and increasing productivity.

This single-disc opener is ideal for clay soils, especially those with sticky clays, and for saline soils, where it is not desired to stir the ground.

Make sure the english subtitles are active or watch full “Single-disc opener for no-till farming ” video in YouTube with english subtitles.

Save Your Time;

Increase Your Profitability With The Single-disc opener!

Single-disc opener - Seeding Disc Hub

Seeding Disc - This is where we made the biggest and best changes:

- The blade hub was redesigned, now housing DOS TWO LARGER BEARINGS with a higher load coefficient.

- New SPLINED SHAFT IS OF LARGER DIAMETER, providing greater tightness thanks to the incorporation of a dust cover that reduces the work of the external lip seals.

- A LONGER BUSHING was incorporated into the design, where the splined shaft is housed that extends the guide capacity, giving more solidity to the assembly.

- The sealing system of the hub has TWO SEALS, one with external lips and the other conventional, which ensures that in the lubrication process with a grease pump, the seals do not slip due to excessive pressure. It is the only greasing point, ONLY ONCE EVERY 500 HECTARES.

It is the only greasing point. Only once every 500 hectares.

Single-disc opener - Leveling Wheel

No more blockages and breaks. Spend more time seeding.

The rubber wheels have very little durability particularly in fields with soybean stubble.

Another very common problem is in soils with excess moisture and large volume of stubble, is the gauge wheel blocking.

The solution to these problems:

We incorporate a semi-pneumatic tire that we manufacture using an anti-friction urethane polymer. We redesigned it using innovative materials for a smooth and self-cleaning operation. It combines technology and functionality to provide exceptional performance in the field.

- A URETHANE GAUGE WHEEL is incorporated as part of the base model, eliminating the previous cleaning conical boron steel extension.

- A new SIX-SPOKE HUB CENTERwas added.

- The hub now has a MAINTENANCE-FREE KRRS double-shielded double-row ball bearing.

Increase your productivity and efficiency in planting with a state-of-the-art regulating wheel.

Get informed now!

Single-Disc Opener - Shoe

We made The shoe of ferritic nodular cast iron, and at the bottom of this piece, a contribution of tungsten electrode is made to increase its useful life.

The new design of the shoe, narrower than the previous one, allows a more stable planting depth and less soil removal, preserving moisture, which will allow the crops a quick and uniform emergence, significantly improving their chances of a higher yield.

We designed the shoe to fit the blade, thus preventing the ingress of dirt, straw, etc. and preventing the body from getting stuck.

The shoe system has the possibility of being regulated in three height levels. To extend the blade’s life, lift the fuse bolt one notch of the three height positions to compensate for wear.

At the seed’s exit, the fertilizer, together with the blade, generates a chamber inside the groove. This avoids the need for a tab to keep the seed inside the groove, and at the same time, the plastic tail would alter the uniformity and distribution of the seeds.

Achieve efficiency in planting.

Single-Disc Opener - Urethane Firming Wheel

Thinner Than The Previous Ones.

The new URETHANE WHEEL is now narrower and more flexible, so it fits better in the furrow, helping to improve the contact of the seeds with the soil and preventing the seed from making contact with the air and, therefore, the proliferation of fungi. It has a spring that adjusts the pressure according to the terrain conditions.

It has a MAINTENANCE-FREE, double-shielded KYY3 bearing, steel on the outside and a Viton seal unit in the second plane (FKM or vinylidene fluoride). These elements provide more significant tightness and protect the bearing against the ingress of garbage and premature wear.

On the other side of the wheel, we place a Viton counter-seal that fits on a spacer, which gives the precise height between the arm and the wheel. These improvements prevent the possibility of garbage ingress.

Are you looking for a solution for sowing in wet and sticky soils?

PLASTIC FIRMER TAB: it has an adjustable spring regulator and two fastening screws that are screwed directly into the shoe.

- It does not allow the rebound of the seed or the jamming

- Maintains a very good contact with the seed, fixing it at the bottom of the furrow

- Ideal for sticky and greyed floors

Make sure to make the best possible sowing in different ground conditions.

Get more information and boost your results!

Single-Disc Opener - drop tubes

Optimized seed/ fertilizer-lowering system

We optimise the independent seed and fertiliser lowering system using plastic tubes jacketed 6 cm (2.36 inches) inside the shoe. This system avoids all possible contact with any metal surface, helping prevent moisture condensation phenomena and the consequent fertiliser clogging.

The seed falls vertically by gravity, avoiding needing a plastic tail.

Optimize your planting – Shoes and Tubes without clogging!

Single-Disc Opener - Optimized Capping System

Optimize your agricultural production!

Single-Disc Opener - Robust Structure and Better Joints

We machine the main arm in a single operation in a machining centre, eliminating dimensional errors. All structural components are made of ferritic matrix nodular cast iron, which offers excellent resistance to torso bending, allowing the part to resume its original geometry in an extreme overload situation thanks to its elasticity.

As for the wheel, tread and capper joints, significant improvements have been incorporated, such as a treated hub made of high-quality cemented and ground non-deformable steel with a hardness of more than 64 RC, which guarantees its durability.

In addition, instead of placing them flush with the body, they are incorporated 5 millimetres into the interior, and a small-sized seal is housed but has enough capacity to stop the entry of dirt, water and pollutants.

The assembly process includes permanent shaft lubrication that eliminates the need for a lubrication zerk, ensuring optimal performance and increased assembly durability.

Take advantage of the strength and durability of our row-units.

Single-Disc Opener - Row-Unit flange

Better bite against the tool holder bar

As the seeding disc is inclined 7º, it produces an intense lateral effort trying to move the bodies on the tool holder bar.

We also modified the anchoring system; it now has a flange cover cast in nodular steel. The clamping row-unit flange has a much more aggressive bite on the toolbar to avoid axial displacement.

Take advantage of the strength and durability of our openers.

Single-Disc Opener - Eje Pivot

New Lubrication System.

In addition, among the improvements, we include lubrication oil in the pin or shaft of the main joint of the opener, allowing minor maintenance just once a season. Each pump of grease injected by the zerk comes out through tiny holes at the pin ends, generating a trap in the groove that lubricates the joint and works as a retainer. The pin is of non-deformable steel with heat treatments reaching hardness values of 64 Rockwell, avoiding premature wear.

Take advantage of the strength and durability of our openers.

Single-Disc Opener - Compression system

Corrosion Resistance Improvements.

In the case of the compression system, improvements have been implemented in the surface to combat corrosion.

The pressure unit maintains a spiral system of very high hardness, capable of resisting up to 300 kilos per body per seeding line. A bolt with a washer indicates the working pressure by generating light between the washer and the casting body. The greater the light (space between), the greater the pressure.

Corrosion resistance is an important aspect and not only aesthetic. We use chrome plating throughout the separator, stud and flange package, and dual-component polyurethane paints with a furnace flash stroke to ensure excellent corrosion resistance. This improvement provides a better yield and a longer service life for the opener.

Protect your investment with our corrosion resistance system.

Just with the information, you do nothing!

da el siguiente paso!

If you have come this far, you have already gathered all the necessary information, but information alone does nothing. Now is the time to act.

Request your quote and complete the circle!