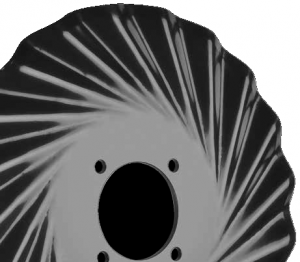

Improved closing Wheel.

The new URETHANE WHEEL is now narrower and more flexible, so it fits better in the furrow, helping to improve the contact of the seeds with the soil and preventing the seed from making contact with the air and, therefore, the proliferation of fungi. It has a spring that adjusts the pressure according to the terrain conditions.

It has a MAINTENANCE-FREE, double-shielded KYY3 bearing, steel on the outside and a Viton seal unit in the second plane (FKM or vinylidene fluoride). These elements provide more significant tightness and protect the bearing against the ingress of garbage and premature wear.

It is manufactured with a forged mass, bearings, and seals prepared for more demanding jobs. The force on the wheel is transferred by a spring with three regulation points, regulating the pressure according to the required needs.

Important: Make the seed pressing arm swing and check that it does not have contact with the plastic pipes of the planting shoe.

We include a plastic cup that houses a very sharp-lipped FRONT LIP RETAINER, capable of sealing the deformations of the metal sheet, producing an additional hermetic shielding.

On the other side of the wheel, we place a Viton counter-seal that fits on a spacer, which gives the precise height between the arm and the wheel. These improvements prevent the possibility of garbage ingress.

- The self-locking nuts should be adjusted so 3 or 4 screw threads protrude.

- Swing the seed pressing arm and check that it does not come into contact with the plastic pipes of the planting shoe.

- The spring lock should be positioned in the middle of the slider. The seed pressing arm should be flat and its holes at 90º.

The force on the wheel is transferred by a spring with three adjustment points, allowing the pressure to be regulated according to the needs required.

NOTE:

Minimum counterpressure point: This is used for seeding on a flat surface or to reduce mud buildup on the wheels when working in wet conditions.

Maximum counterpressure point: Used for deep seeding.

Are you looking for a solution for sowing in wet and sticky soils?

PLASTIC FIRMER: it has an adjustable plastic spring and two fastening screws that are screwed directly into the shoe.

- It does not allow the rebound of the seed or the jamming

- Maintains an excellent contact with the seed, fixing it at the bottom of the furrow

- Ideal for sticky and clayey floors

Make sure to make the best possible sowing in different ground conditions.

Get more information to boost your results!

WhatsApp us

WhatsApp us