Single Disc Opener With Parallelogram TURBOSEM

Buying is easy:

Contact us and we will send it to you!

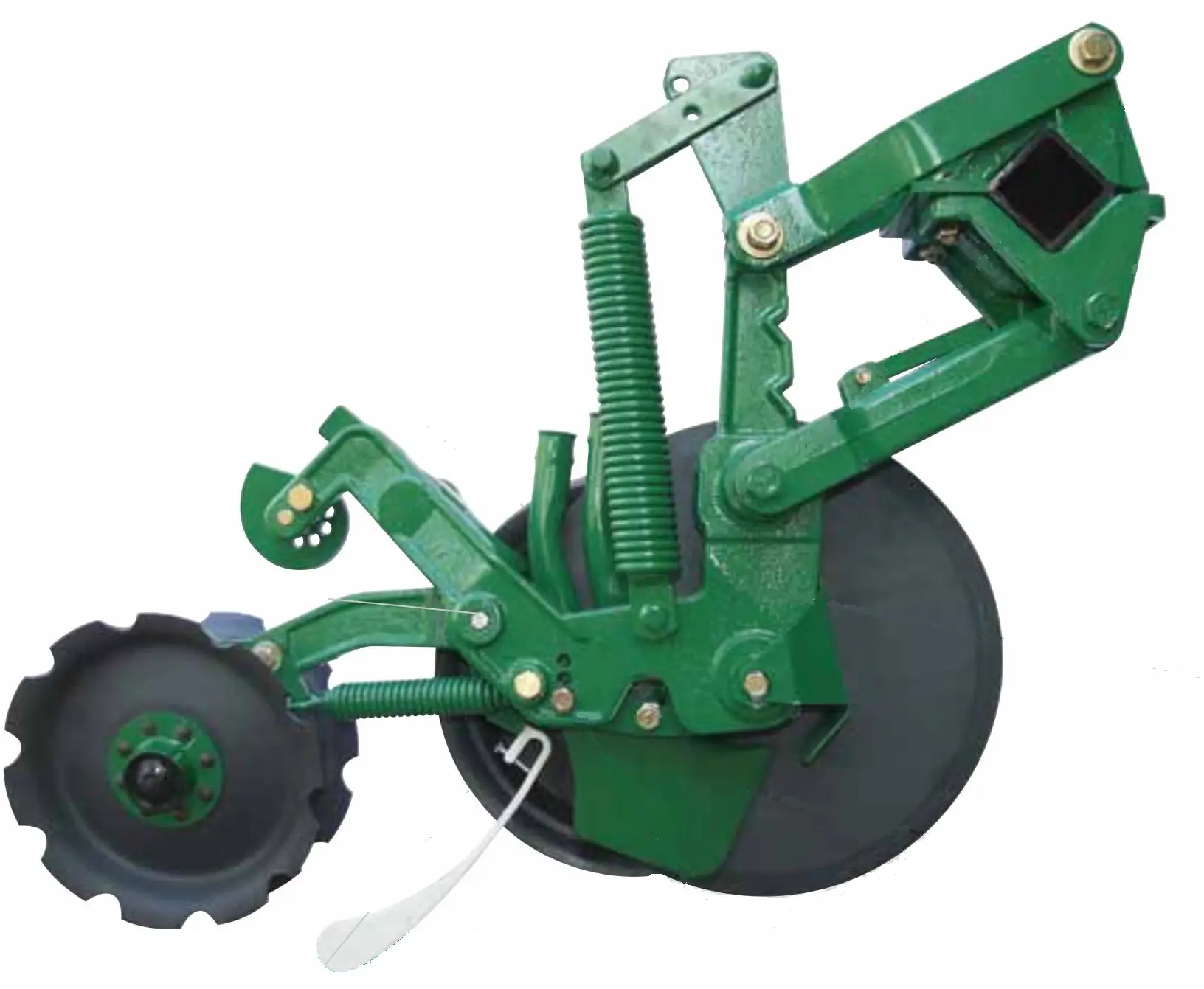

Single Anchor Point

When the planting unit encounters variations in the topography or differences in the volume of stubble on the ground, the mechanism assembly oscillates around a pivot point, moving up and down. These movements constantly alter both the point where the seeds are deposited and the incision angle of the disc, affecting its efficiency in cutting residues and its penetration capability into the soil.

Advantages

- Uniform planting depth, even on uneven soils.

- Consumes less power.

- Less soil removal

- It helps to retain moisture.

Seeding blade

Grain presser

Depth control

Discharge pipes

Furrow closed

Advanced Engineering Solutions for Maximum Durability and Performance

Designed for efficiency and durability in demanding environments, these rigid ball bearings are pre-lubricated to ensure optimal performance from the first use. The pre-lubrication extends the bearing’s lifespan, reducing the need for maintenance and enhancing the reliability of your machinery.

Lower Parallelogram in Austenitic-Perlitic Nodular Steel:

This component is manufactured from high-quality steel to withstand the intense lateral forces generated during disc operation. Its exceptional robustness ensures outstanding durability under extreme conditions, making it the perfect choice for operations that demand maximum strength and efficiency.

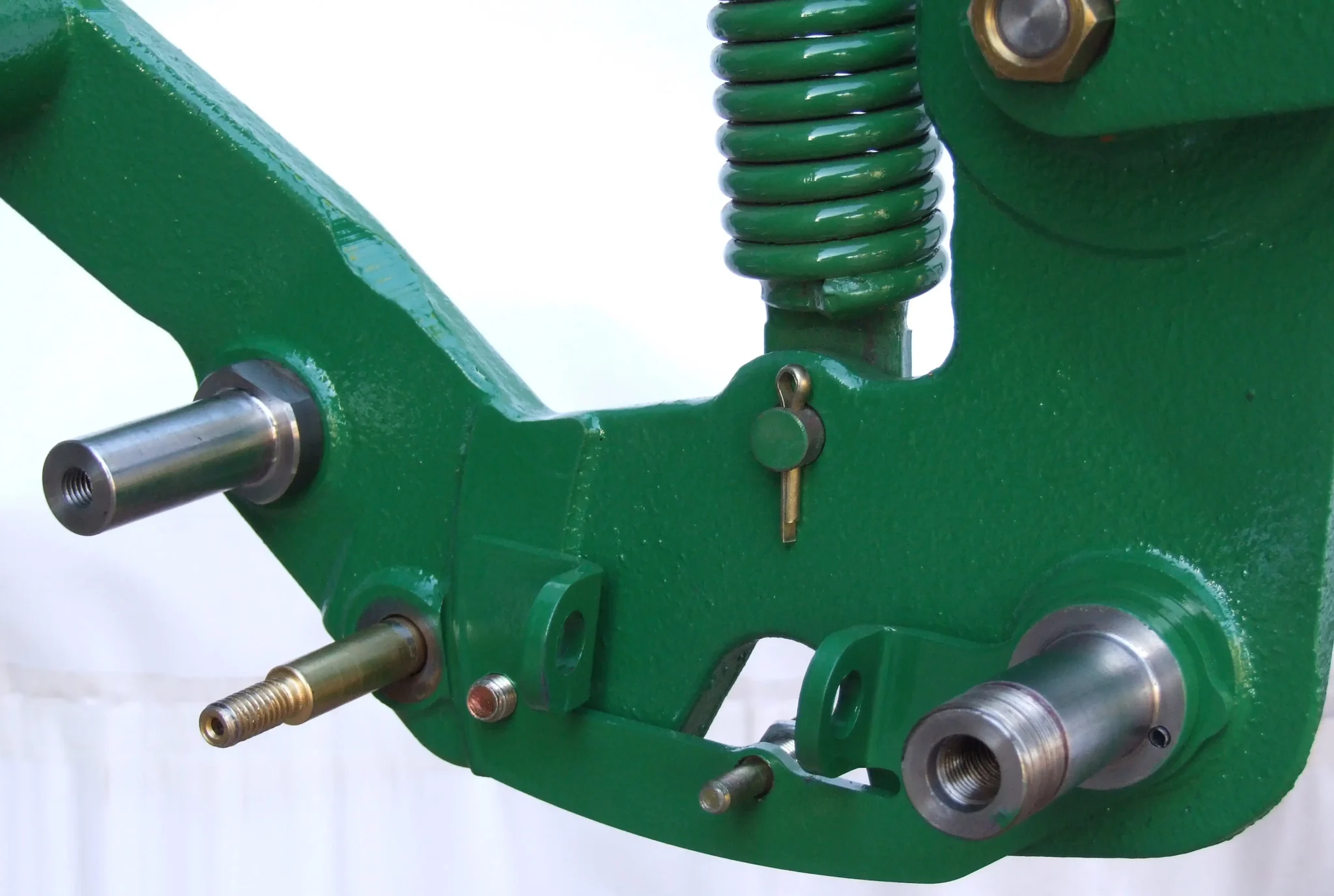

Equipped with high-precision tapered roller bearings, the anchor system allows fine adjustments to perfectly suit your operational needs. These pre-lubricated bearings offer simple installation and easy adjustment, ensuring efficient and consistent performance.

The nodular cast iron arm we offer is specially designed to ensure strength and durability in demanding applications. This component integrates fully replaceable shafts and pins, facilitating maintenance and extending the equipment’s lifespan.

Advanced Manufacturing for Maximum Strength:

Manufactured from nodular cast iron, the arm stands out for its ability to withstand high tensions and loads without compromising its structural integrity. The choice of this material reinforces confidence in its continuous performance under adverse operating conditions.

The incorporation of fully replaceable shafts and pins is a clear testament to our commitment to efficiency and practicality. This modular design not only simplifies maintenance tasks but also reduces downtime, allowing for quick and effective replacements without the need for complex disassemblies.

This strategic approach in the design and manufacturing of the nodular cast iron arm ensures that it can meet the most rigorous challenges of its operating environment, providing exceptional long-term value.

The shoe is not only treated to offer exceptional hardness but also incorporates an advanced, patented flotation system that ensures constant contact with the disc. This feature is crucial for maintaining precision and efficiency during planting and fertilizing in various soil conditions.

Enhanced Durability and Precision:

The hardness treatment applied to the shoe ensures its resistance to wear and abrasion, significantly extending its lifespan and maintaining optimal performance in challenging terrains.

Our patented flotation system is a game-changer, allowing the shoe to dynamically adjust to terrain irregularities. This ensures that the shoe maintains uninterrupted contact with the disc, which is essential for consistent and effective planting and fertilizing.

Independent Seed and Fertilizer Distribution:

Additionally, the seed and fertilizer tubes are independent, enabling more controlled and precise distribution. This separation allows for specific adjustments to the application rates of seeds and fertilizers, improving input efficiency and optimizing crop growth. This combination of durability, technological innovation, and precision in input distribution places our planting unit at the forefront of the industry, providing effective and reliable solutions for modern agriculture.

Our patented depth regulation system for the shoe sets a new standard in agricultural machinery, significantly increasing the lifespan of the shoe-disc assembly. This innovative system offers three adjustable positions, allowing for precise adaptation to specific terrain and crop needs.

Increased Durability:

By enabling precise depth adjustments of the shoe, irregular wear is reduced, and the operational life of critical components is extended, ensuring that both the shoe and the disc work more efficiently and for longer periods.

The system offers three distinct configurations, providing versatility for different soil types and planting techniques. This not only enhances the equipment’s adaptability but also optimizes the placement of seeds and fertilizers, which is crucial for successful cultivation.

Patented Technology for Better Planting:

This regulation system not only protects the equipment but also ensures more uniform and effective planting, resulting in more homogeneous crop growth and improved yields. This focus on precision and durability underscores our commitment to innovation and quality, offering farmers a robust tool that effectively adapts to their operational needs, significantly enhancing both productivity and profitability.

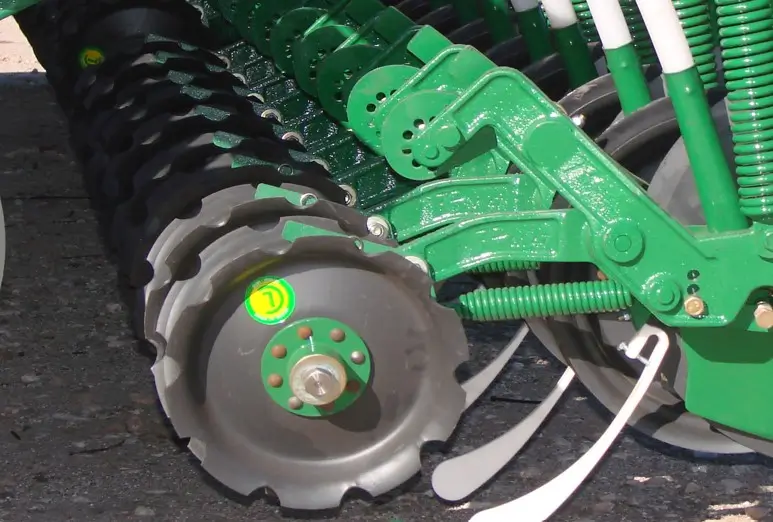

Our leveling wheel is designed with a metal lip rim that includes a cleaner, enhancing both functionality and durability. This innovative design allows for easy removal of the leveling wheel-arm assembly, optimizing maintenance and equipment adaptability.

Metal Lip Rim with Integrated Cleaner:

The inclusion of a cleaner in the metal lip rim ensures that the wheel remains free of debris, which is essential for maintaining efficiency and precision during soil leveling. This design eliminates obstructions that could affect machinery performance, ensuring smooth and continuous operation.

The ability to easily remove the leveling wheel and arm assembly facilitates both routine maintenance and necessary repairs. This modular feature ensures that adjustments or replacements can be carried out quickly, minimizing downtime and maximizing operational efficiency.

Productivity Optimization:

The advanced design of our leveling wheel directly contributes to better soil management, which is crucial for uniform planting and optimal crop growth. By maintaining constant and effective contact with the soil, this wheel ensures precise leveling, fundamental for soil preparation in modern agriculture. This integrated approach to innovation and functionality in the leveling wheel underscores our commitment to developing agricultural solutions that enhance productivity and profitability for farmers in all types of cultivation conditions.

Our closing disc set offers unprecedented versatility thanks to its serrated design. This system allows the option to remove one of the discs if working conditions require it, effectively adapting to various situations and soil types. This adjustment can be crucial for optimizing machinery performance under specific conditions, allowing for customization based on operational needs at the moment.

The rocker arm of the closing discs is equipped with a rigid ball bearing, ensuring smooth and consistent movement. This feature is essential for maintaining the efficiency of the closing discs, providing stability and precision during operation. Rigid ball bearings are known for their durability and resistance, minimizing maintenance and improving system reliability in the field.

Key Benefits:

– Adaptability:

The ability to modify the configuration of the closing discs according to specific needs enhances the versatility of the machinery.

– Durability and Reduced Maintenance:

The use of rigid ball bearings in the rocker arm reduces the need for frequent maintenance, resulting in less downtime and lower operational costs.

– Effective Operation:

The optimized design of the rocker arm and discs ensures smooth and effective operation, which is crucial for achieving optimal work results. This focus on the integration of high-quality components and modular design underscores our commitment to innovation in agricultural machinery, offering solutions that directly address the needs of modern farmers.

Discover the Cutting Edge in Agriculture with the TURBOSEM Planting System

Advanced Precision in Every Element

Each TURBOSEM unit is meticulously adjusted to achieve perfect uniformity in planting depth. This precise adjustment ensures that each seed is planted at the ideal depth, promoting uniform and healthy growth.

Stability and Perfection on Uneven Terrain

Equipped with an innovative parallelogram system that connects the unit to the frame, the TURBOSEM planting body maintains the perpendicularity of the shoe to the ground at all times. This design allows the shoe to maintain a constant attack angle, ensuring that seeds and fertilizer are deposited at optimal depths, regardless of terrain irregularities.

Exceptional Cutting and Placement

Outfitted with a robust 17 3/4″ disc and an efficient shoe, the TURBOSEM unit precisely cuts through stubble and opens uniform furrows for planting. This system not only improves planting efficiency but also ensures that each grain and dose of fertilizer is placed in the exact location to maximize the yield of each crop.

Download technical sheet

Depth control wheel cleaning system

The cutting disc cleaning system allows it to work on wet soil, significantly extending the planting window and consequently enhancing the performance of planters equipped with this unit.

For no-till planting, the applied pressure should not be less than 175 kg. This planting unit led to the development of fine grain planters by the Argentine company Pierobon and the Ukrainian company AGRO SOYUZ, with their “Turbosem II” and “MD 19-40” versions.

This planting unit offers two configurations: seeds only or seeds and fertilizer. This option is available upon customer request.

Seed Presser

- It does not allow the rebound of the seed or the jamming

- Maintains a very good contact with the seed, fixing it at the bottom of the furrow

- Ideal for sticky and greasy floors

Plastic firmer: it has an adjustable plastic spring and two fastening screws that are screwed directly to the shoe.

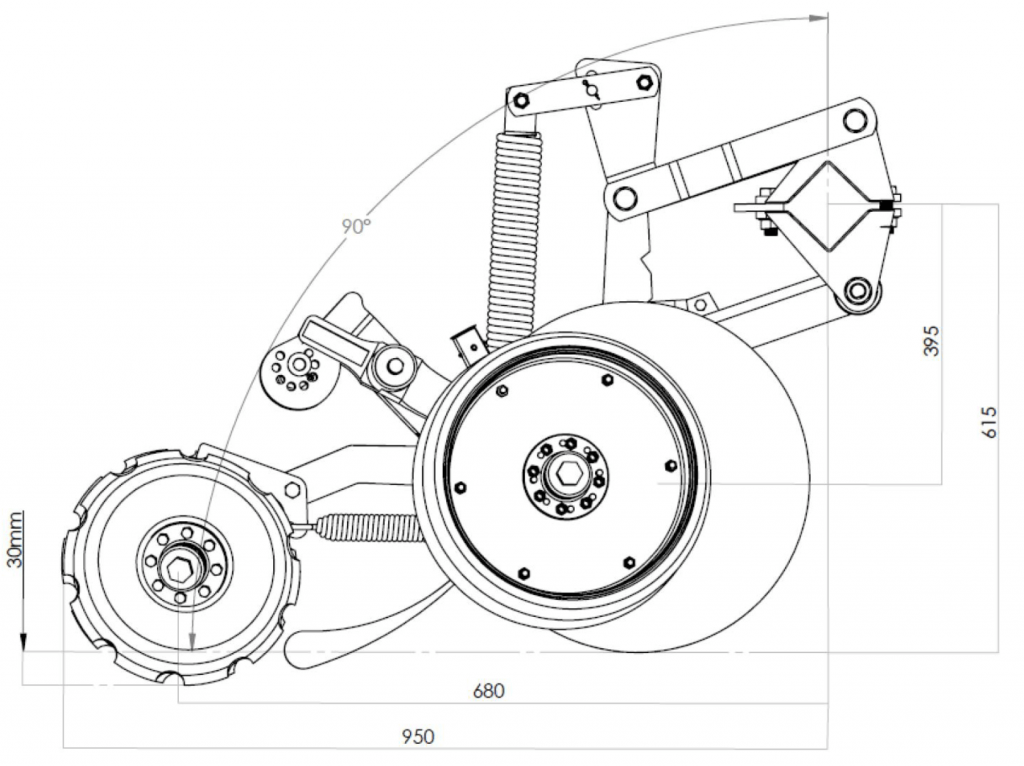

General Dimensions