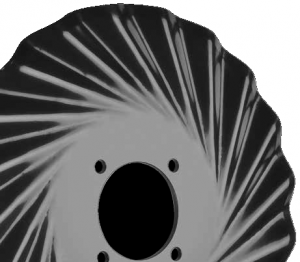

The shoe is made of nodular cast iron, with a tungsten contribution in its area of greatest wear (Hard Facing).

It has two independent downspouts, one for the fertilizer and one for the seed.

Both pipes have a straight and independent drop, which means there is no possible clogging.

In the same pipe for the seed fall, there is a smaller diameter pipe for pasture sowing.

It must be controlled that the location of the seed and fertilizer drop spout is located in the middle of the space left between the blade and the seed squeezing arm.

The hard filler in the lower zone of the shoe must be such that it has a neat surface and that there is no filler material in the ground zone of the shoe, thus ensuring good contact between the blade and the shoe.

Verify that the shoe can swing freely by rotating on the fixing bolt.

The following precautions should be taken for a correct operation and a longer duration of the planting set.

- The shoe must oscillate freely through its fixing screw, whereby the action of the spring will ensure a firm contact between the disc and the shoe. In addition, this oscillation allows the self-cleaning of the shoe at the time of planting. In case of high humidity, a manual cleaning should be carried out.

- If there is no pressure between the shoe and the disc, the plate spring must be replaced.

- The prisoner must allow an opening of 2.5 cm in the lower area of the shoe to enable a correct self-cleaning of the assembly.

- It must be ensured that there is always firm contact between the shoe and the disc.

Damages due to poor regulation

If the above working conditions are not met, there is a risk of damaging the unit and the following may occur:

- Premature and uneven shoe wear.

- Premature wear of fixing holes in the main arm unit.

- Premature wear of the fixing hole in the shoe.

- Breakage in disc holder hub screws.

- Breakage of the shoe’s screw.

Adjustment of the shoe height

The shoe’s placement in each fixing hole in the drawbar will depend on the seeding type and the disc’s wear.

The shoe can be fixed in the upper hole for:

- Compensate for the wear of the blade.

- Reduce the wear of the shoe when sowing deep.

- Reduce the accumulation of garbage between the shoe and the blade.

The shoe can be fixed in the bottom hole for:

- Sow to depths of 30 mm or less.

- Planting in conditions of excess litter.

- When using a worn shoe with a new blade.

- When a high sowing speed causes an irregular sowing depth.

Caution:

Always ensure that the disc extends below the shoe by 5 to 10 mm; otherwise, the main arm of the unit may be damaged. At this point of disc wear, you can move the shoe to the position of the next hole up or replace the cutting disc.