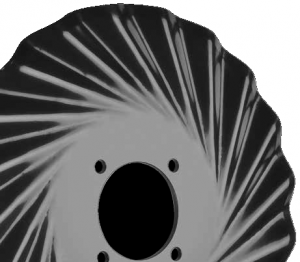

DISC HOLDER HUB, ASSEMBLY AND ADJUSTMENT

ASSEMBLY:

- The blade hub was redesigned, now housing DOS TWO LARGER BEARINGS with a higher load coefficient.

- New SPLINED SHAFT IS OF LARGER DIAMETER, providing greater tightness thanks to the incorporation of a dust cover that reduces the work of the external lip seals.

- A LONGER BUSHING was incorporated into the design, where the splined shaft is housed that extends the guide capacity, giving more solidity to the assembly.

- The sealing system of the hub has TWO SEALS, one with external lips and the other conventional, which ensures that in the lubrication process with a grease pump, the seals do not slip due to excessive pressure. It is the only greasing point, ONLY ONCE EVERY 500 HECTARES.

ADJUSTMENT

A torque meter should be used, positioning in 15 kg of pressure and starting the adjustment by rotating the blade until the safe of the torque meter jumps.

FINAL VERIFICATION OF THE SUBSET

Check that the blade rotates freely, giving it a manual boost. (Lift the shoe so that it does not have contact with the blade, and check that the rubber is also not in contact with the blade.) In addition, check that there is no play between the shaft and the hub subassembly, thus ensuring that the preload spacer has been correctly arranged.

Caution: Do not wash the bearings with kerosene; this product forms a film that prevents the lubricant from adhering to the rollers, causing overheating and damaging the bearings.

RECOMMENDATIONS

- The opener is pre-greased from the factory, but it is advisable to grease the blade holder dough before starting the seeding for the first time.

- If the blade holder dough does not have enough grease, the service life of the tapered bearings is drastically reduced.

- It should not be greased excessively as it may cause the seals of the knife-holder dough to break.

- Check that the adjustment of the two tapered bearings is not weak (this is noticeable in that the blade has lateral play when moving it manually). This defect can cause the breakage of the bearing basket and thus decrease the useful life of the bearing, being able to generate the breakage of the blade and the bearing.

- In addition, an excessive adjustment of the tapered bearings will produce a lot of friction and overheating in the dough, which will destroy the bearings (the blade must be able to be rotated manually, without lateral play).

- Grease the first 10 hectares per planting body; for example, if the planter has 48 units, at 480 hectares, it should be greased and checked if the bearing does not take play. If I take play the bearing, adjust it according to procedure.

- Grease again at 25 hectares per planting body; for example, if the planter has 48 units, at 1200 hectares, it must be greased and checked if the bearing does not take play. If I take play the bearing, adjust it according to the procedure.

- At 50 hectares (if the planter has 48 units, it is equivalent to 2400 hectares), the play of the tapered bearings should be greased and adjusted. The blade change is performed at this stage, depending on the terrain type.

- At 75 hectares (if the planter has 48 units, it is equivalent to 3600 hectares), the bearing clearance should be greased and adjusted if it is discovered that there is lateral clearance on the blade.

- Between 75 and 100 hectares, depending on the aggressiveness of the terrain, the conical bearings and seals must be changed. If the field is very aggressive, it is recommended to increase the oiling frequency and check the blade’s lateral play.