It mainly comprises a high-strength, high-quality coiled spring that withstands high loads during planting. Improvements have been implemented in surface covering systems to combat corrosion. Corrosion resistance is an important and not just aesthetic aspect. A chrome plating is applied to the entire package of the separator, stud, and flange to ensure excellent corrosion resistance and a two-component polyurethane paint with a flash bake. This improvement ensures better performance and a longer service life for the seeding unit.

IMPORTANT: It is necessary to check that the separator pipe is not deformed to achieve free circulation through the cast iron bushing. If there is an obstruction, the compression system will not work correctly, destroying the pipe, screw, and flanges.

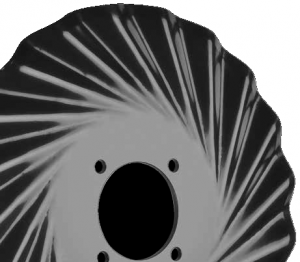

Regulation of the loading pressure

The pressure unit maintains a spiral system of very high hardness, capable of resisting up to 300 kilos per body per seeding line. A bolt with a washer indicates the working pressure by generating light between the washer and the casting body. The greater the light, the greater the pressure.

In case of replacement of any component, care must be taken in the assembly of the same, adjusting the nuts to the pressure defined in the drawing to avoid loosening them or deforming the separator pipe.

Adjust the nut with 5kg/cm2 so as not to damage the ends of the spout.

| Light mm – inches | Load kg – pounds |

| 10 – 0.39 | 150 – 330.69 |

| 20 – 0.78 | 290 – 639.34 |

| 30 – 1.18 | 430 – 947.99 |

| 40 – 1.57 | 550 – 1212.54 |