Optimized Closing System

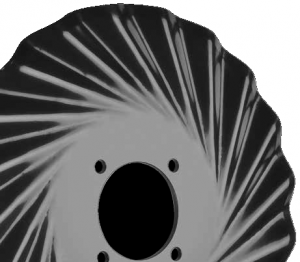

The new capping system features a cast iron wheel with material removed from its centre, which improves the spring performance, prevents rebounds, adjusts the floor and closes the groove on the shoe side.

The innovative capping wheel has a KYY3 type bearing with double shielding, MAINTENANCE-FREE and has two indexing angles, one horizontal and one vertical, which allow the soil extracted by the disc and the shoe to be returned to the furrow and achieve precise compaction on the planting line.

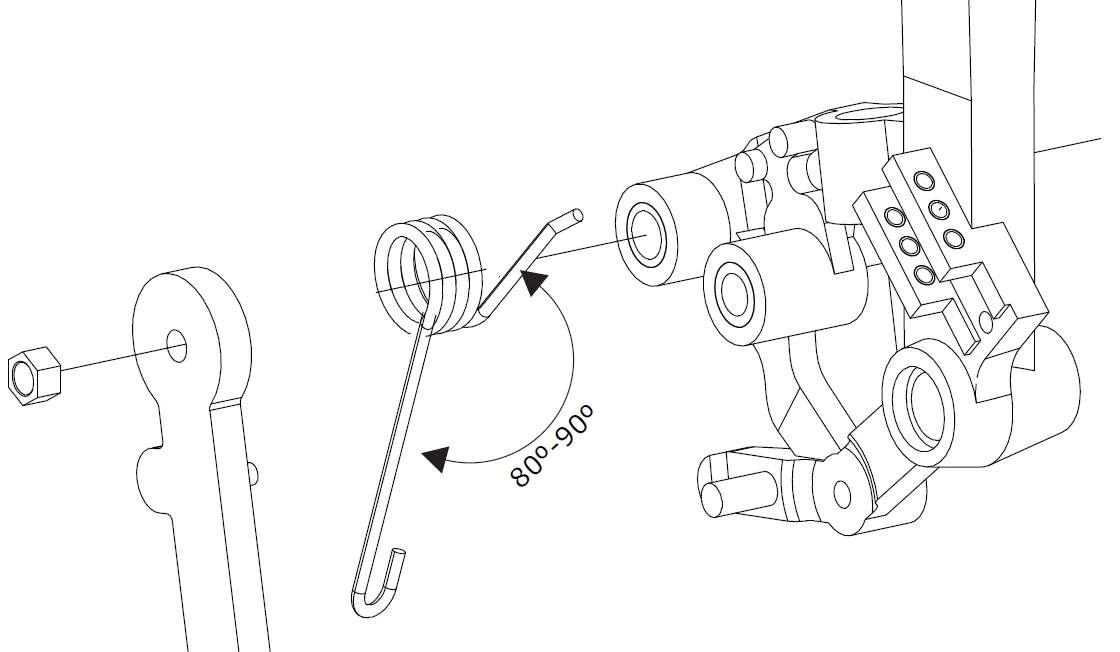

The wheel arm is cast nodular steel and includes an ergonomic spring that facilitates the adjustment of the working pressure without needing tools.

In clay soils: The wheel must be brought closer to the planting line.

On sandy soils: The wheel should be removed from the planting line.

Adjusting the wheel position

It is made through washers that, according to the quantity, will define the position of it. This system has the bearing on the arm instead of the wheel, making it less exposed to contamination.

Caution: Do not wash the bearings with kerosene. This product forms a film that prevents the lubricant from adhering to the rollers, causing overheating and damaging the bearings.

In areas with very uneven terrain, remove pressure to prevent breakages of the capping system.

IMPORTANT: For a good covering of the groove, the spring must have an important pressure so it must be controlled that it has between both sockets from 80º to 90º.