Double-disc seeding unit with parallelogram Original FILAM System

Buying is easy:

Contact us, and we’ll ship it to you !

Double-Disc Seeding Unit:

Specifically Designed for Coarse Grains

The double-disc seeding unit represents a significant advancement in agricultural technology, designed to ensure precise and efficient planting. Here are the key features that make it stand out:

- Triples the lifespan of all main components of the seeding unit.

- More hectares worked with less maintenance.

- Uniform furrow bottom for consistent seed placement.

- Reduced forward resistance for smoother operation.

- Internal edge in the discs keeps them in constant contact.

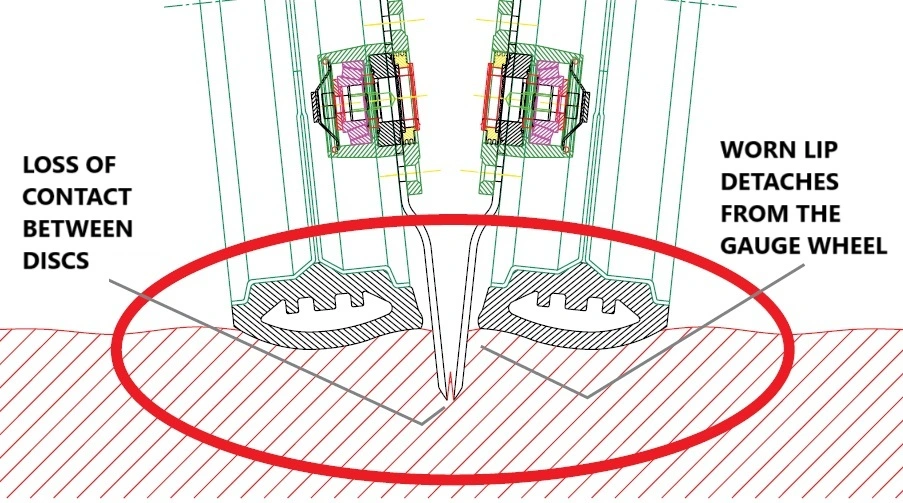

TRADITIONAL SYSTEM with 15 mm wear on the disc radius

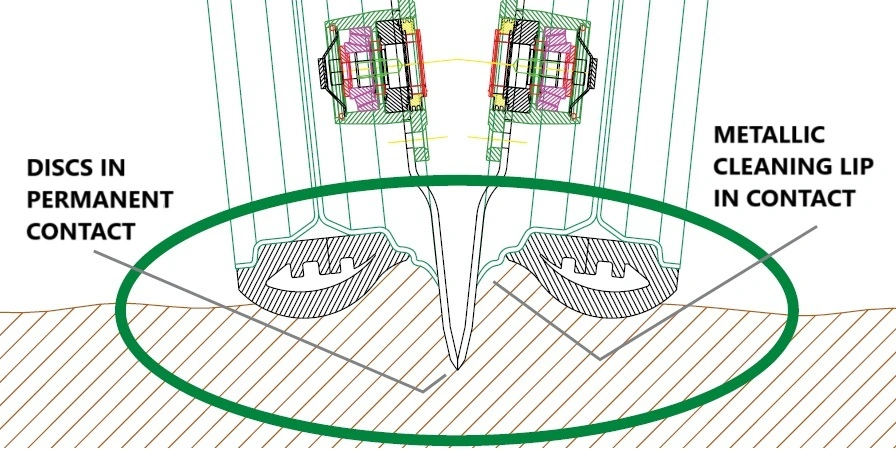

FILAM SYSTEM with equal wear

1. Durability and Consistency of the Internal Edge:

The seeding unit discs maintain their internal edge for almost their entire lifespan, preventing constant adjustments and ensuring a uniform furrow, which guarantees homogeneous emergence and high-quality crops.2. Metallic Lip on the Gauge Wheel:

The lip of the gauge wheel, responsible for cleaning the disc, is now made of metal instead of rubber. Rubber lips tend to break over time, rendering the cover unusable and causing blockages. The metallic lip, which is part of the inner rim of the wheel, is made of boron steel and undergoes a heat treatment similar to that of cutting discs, ensuring greater durability and efficiency.3. Modification of the Cover Profile:

The cover has been redesigned to optimize the furrow formation process. When the disc enters the soil, the displaced soil is lodged in the decompression zone between the cover and the disc, without affecting the support area or altering the leveling. This significantly improves planting and plant development.4. Double-Track Ball Bearing:

The central bearing of the disc has been upgraded from adjustable tapered rollers to double-track ball bearings, eliminating the need for constant adjustments and improving the efficiency of the seeding unit.5. 5 mm Thick Disc with Recessed Center:

The disc, with a 5 mm thickness and a recessed center, features a hub flange located on the inner side. If the disc flexes inward during operation, it does not affect the rivets or break in the center, as seen with other brands. Instead, it rests on the hub flange, ensuring greater stability and durability.Anchor Point with Parallelogram

When the seeding unit encounters variations in topography or differences in the volume of stubble on the field, the entire mechanism oscillates around a pivot point, moving up and down. These movements constantly alter both the point where the seeds are deposited and the incision angle of the disc, impacting its ability to cut through residue effectively and penetrate the soil efficiently.

Advantages

- 100% Maintenance-free.

- Uniform seeding depth, even on uneven terrain.

- Lower power consumption.

- Reduced soil disturbance.

- Helps retain moisture.

Seeding Blades

Seed Presser

Depth Control

Precision Planting

Furrow Closing

Modular Design for Easy Maintenance:

The incorporation of fully replaceable shafts and bolts is a clear testament to our commitment to efficiency and practicality. This modular design not only simplifies maintenance tasks but also minimizes downtime, enabling quick and effective replacements without the need for complex disassembly. This strategic approach to the design and manufacturing of the ductile cast iron arm ensures it can withstand the most demanding operational challenges, delivering exceptional long-term value.Depth Control: Precision and Comfort

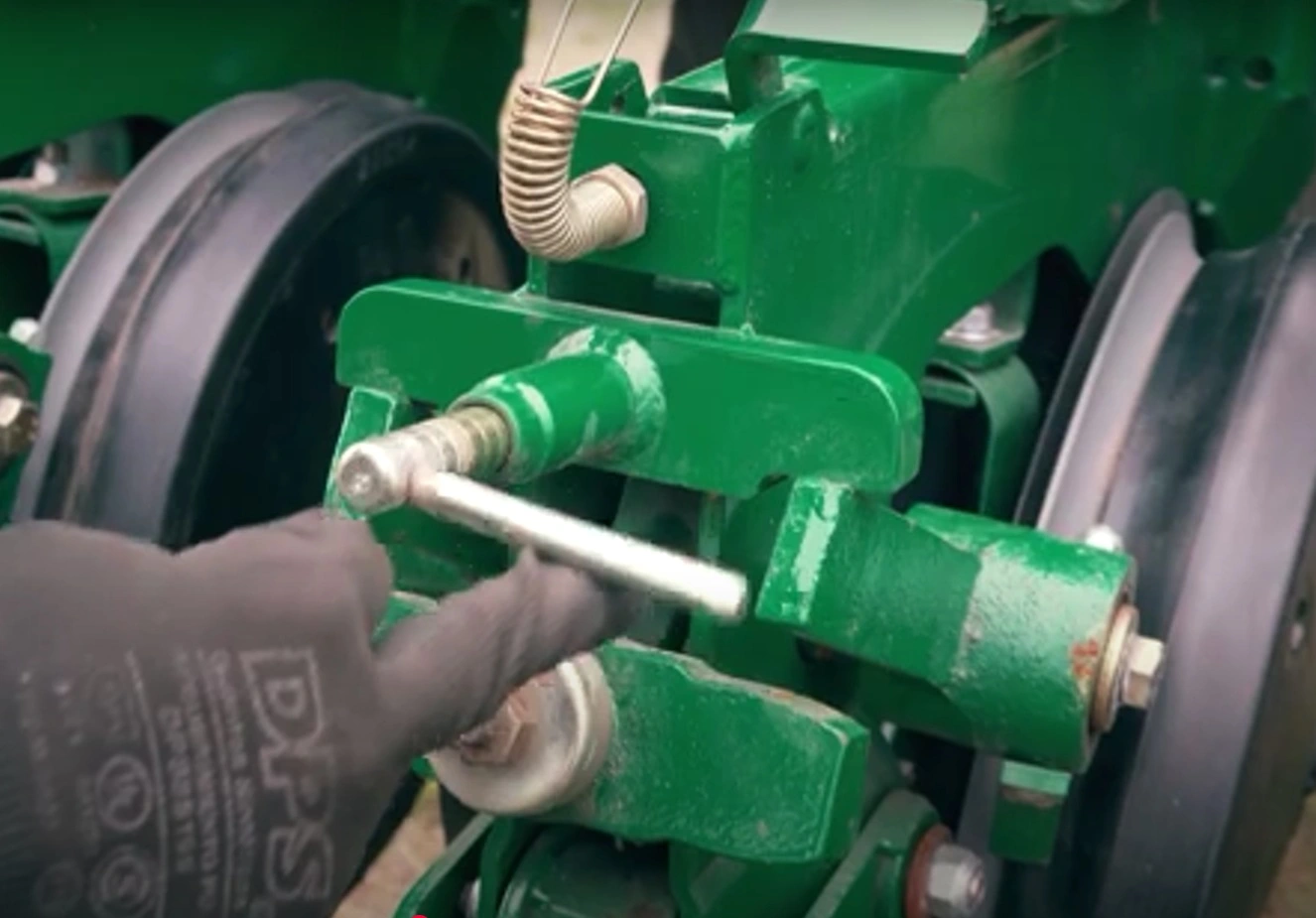

The seeding depth control system is adjusted using a crank, which moves the stop associated with each depth control wheel. This mechanism ensures precise and uniform regulation throughout the entire planter.

Additionally, the system features guide marks that indicate the achieved depth level. Each mark represents one centimeter, making calibration easier and ensuring optimal seeding depth for crop development.

Seed Pressing Tongue

- Prevents seed bounce and clogging.

- Maintains excellent contact with the seed, securing it at the bottom of the furrow.

- Ideal for sticky and clayey soils.

Plastic presser: Features an adjustable plastic spring and two fastening screws that attach directly to the shoe.

Gauge Wheels with Metal Flange Rims

Our gauge wheel is designed with a metal flange rim that includes a cleaner, enhancing both functionality and durability. This innovative design allows for easy removal of the gauge wheel-arm assembly, optimizing maintenance and equipment adaptability.

Metal Flange Rim with Integrated Cleaner:

The inclusion of a cleaner in the metal flange rim ensures that the wheel remains free of debris, which is essential for maintaining efficiency and precision during soil leveling. This design prevents blockages that could impact machine performance, ensuring smooth and continuous operation.

Set of Toothed Closing and Shaping Discs:

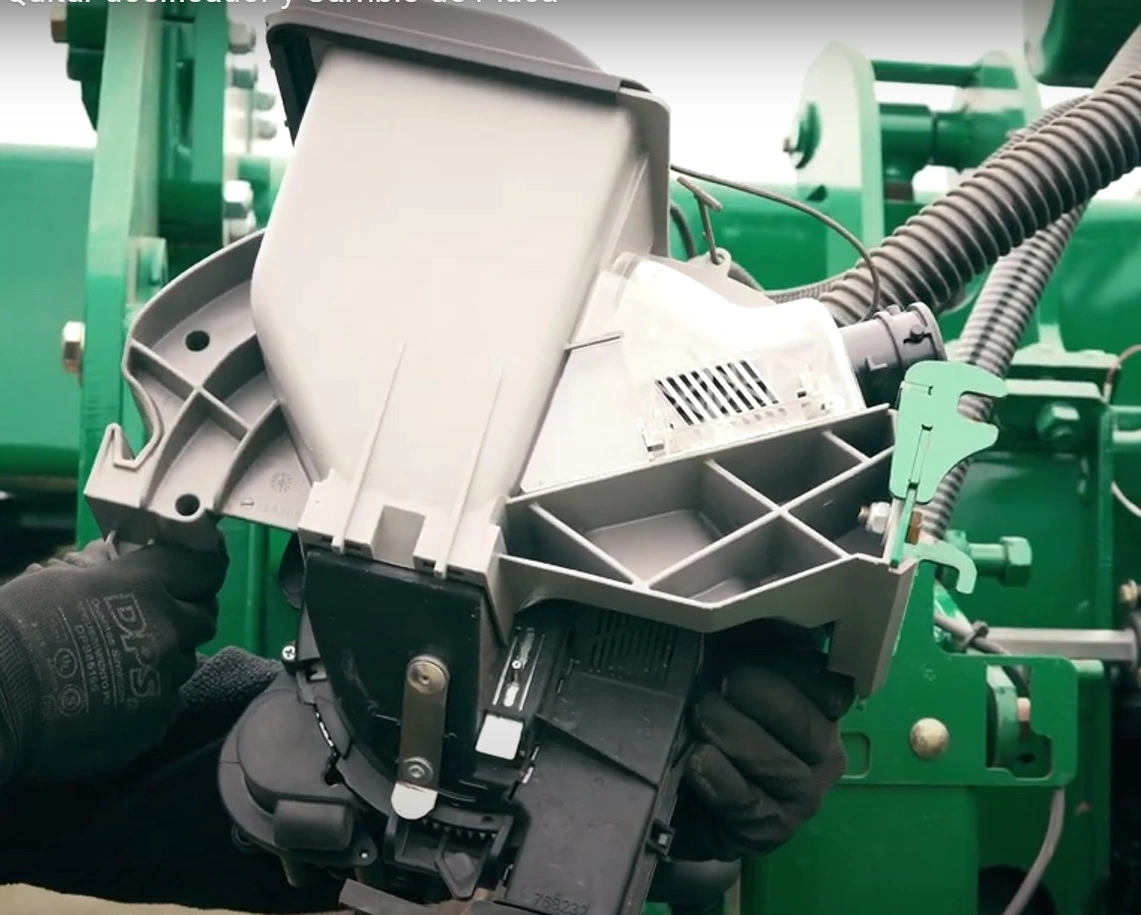

This system allows the option to remove one of the discs if working conditions require it, effectively adapting to various situations and soil types. It enables customization based on operational needs at any given moment. The closing wheel system features two controls: the first adjusts the pressure that the ridge wheels exert on the soil, while the second modifies the attack angle of the wheels to achieve optimal adjustment according to soil conditions and the amount of residue on the surface.Double Disc Units Adapted to Precision Planting Meters

The double-disc planting units are designed to integrate seamlessly with Precision Planting seed meters, offering optimal performance in seed distribution and uniform emergence.

Precision Planting Meters: Innovation in Seeding

Precision Planting meters stand out for their ability to enhance planting efficiency through advanced seed control technology. Their design allows for precise metering, preventing skips and doubles, maximizing germination potential, and optimizing crop yield.

Advantages of Integration with Double Disc Units

✅ Uniform distribution: Ensures even seed placement in the furrow.

✅ Greater accuracy: Reduces variability in planting, improving emergence.

✅ Adaptability: Works in various soil types and residue conditions.

✅ Optimized yield: Minimizes waste and maximizes field efficiency.

The combination of double-disc units with Precision Planting metering systems offers an advanced solution for more efficient and high-performance planting.