Steps to Follow:

Adjust the Sowing Depth

- Loosen the pressure on the covering wheels and the seed-pressing wheel.

- Adjust the depth by acting on the perforated plate, and with the handle move up or down one point at a time.

- Once the sowing depth is set, adjust the body’s spring compression to ensure enough force on the ground, preventing the body from detaching from the soil during sowing.

Verification:

Work at the sowing speed (6 to 8 km recommended – Do not exceed 10 km/h).

How to Determine Sowing Speed?

The sowing speed will be determined by the sowing quality achieved, which, in turn, will depend on the soil and weather conditions. The body shouldn’t be loose, but it also shouldn’t be so tight in the soil that it leaves a deep mark. To achieve the right balance, it will be necessary to adjust the hydraulic cylinder’s pressure that controls the sowing body package.

IMPORTANT: Adjust the pressure of the seed-pressing wheel until the seed makes contact with the soil at the bottom of the furrow. Then, follow these steps:

1. Covering Wheels: Adjust the covering wheels to achieve the desired furrow cover.

2. Fertilize or Add Soil: To add or contribute soil to the furrow, adjust the wheels through the guide and twist the load spring more. You can also place the toothed supplements on the inside to reduce soil removal, or remove them if there’s long residue (like sorghum or sunflower).

3. General Adjustment: Adjust all the bodies equally to the first benchmark and operate the seeder at the desired sowing speed to observe its general behavior.

NOTE: It may be necessary to adjust the cylinder’s travel that controls the body package.

IMPORTANT: Recommendations and Warnings

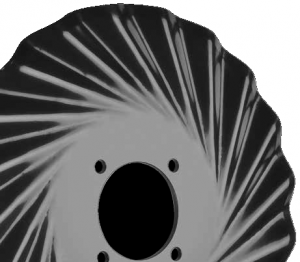

- Check the correct assembly and adjustment of the blade holder hub. A loose blade shortens the bearing’s lifespan.

- Inadequate or excessive adjustment of the 2 tapered bearings will affect their performance, possibly damaging the blade or shortening its lifespan due to friction heating.

- Ensure the blade holder hub is greased at the start of its work (See maintenance instructions).

- DO NOT TURN AT THE HEADLAND without first lifting the bodies, as this will cause breakages.

- In wet grounds with stubble, use the appropriate options of depth-controlling wheels.

- Along with checking the blade’s wear, inspect the shoe’s position to prevent breakages.